WHAT WE OFFER

We Are Dedicated To Serve You All Time.

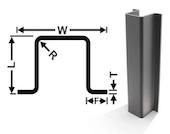

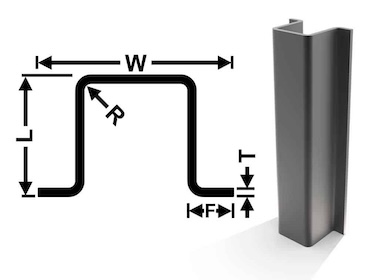

C Lip & Z Channel

Material available - Magsure, Galvanium, Pre GI/GP, Hot Galvanised, HR(black), Stainless Steel.

Size c channel - width:75mm- 300mm; height: 30mm - 80mm; lip: 10mm - 20mm; thickness:1mm X 3mm

Size z channel - width:120mm- 300mm; height: 30mm - 80mm; lip: 10mm - 20mm; thickness:1mm X 3mm

Punching facility available (on request)

Hat Profile

Material available - Magsure, Galvanium, Pre GI/GP, Hot Galvanised, HR(black), Stainless Steel.

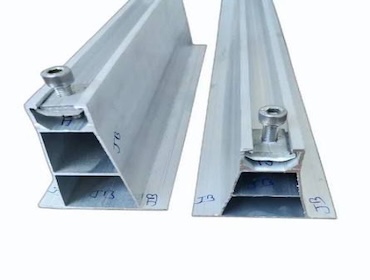

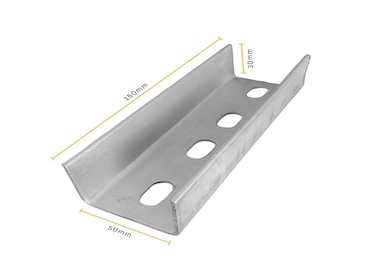

Strut Channel

Material available - Magsure, Galvanium, Aluminium, Pre GI/GP, Hot Galvanised, HR(black), Stainless Steel.

Size - 41mm X 21mm; 41mm X 41mm; 41mm X 62mm; 41mm X 82mm

Categories: plain/ slotted.

U Channel Profile

Material available - Magsure, Galvanium, Pre GI/GP, Hot Galvanised, HR(black), Stainless Steel.

Size c channel - width: 80mm- 300mm; height: 40mm - 80mm;

thickness:1.5mm X 3mm (on request)

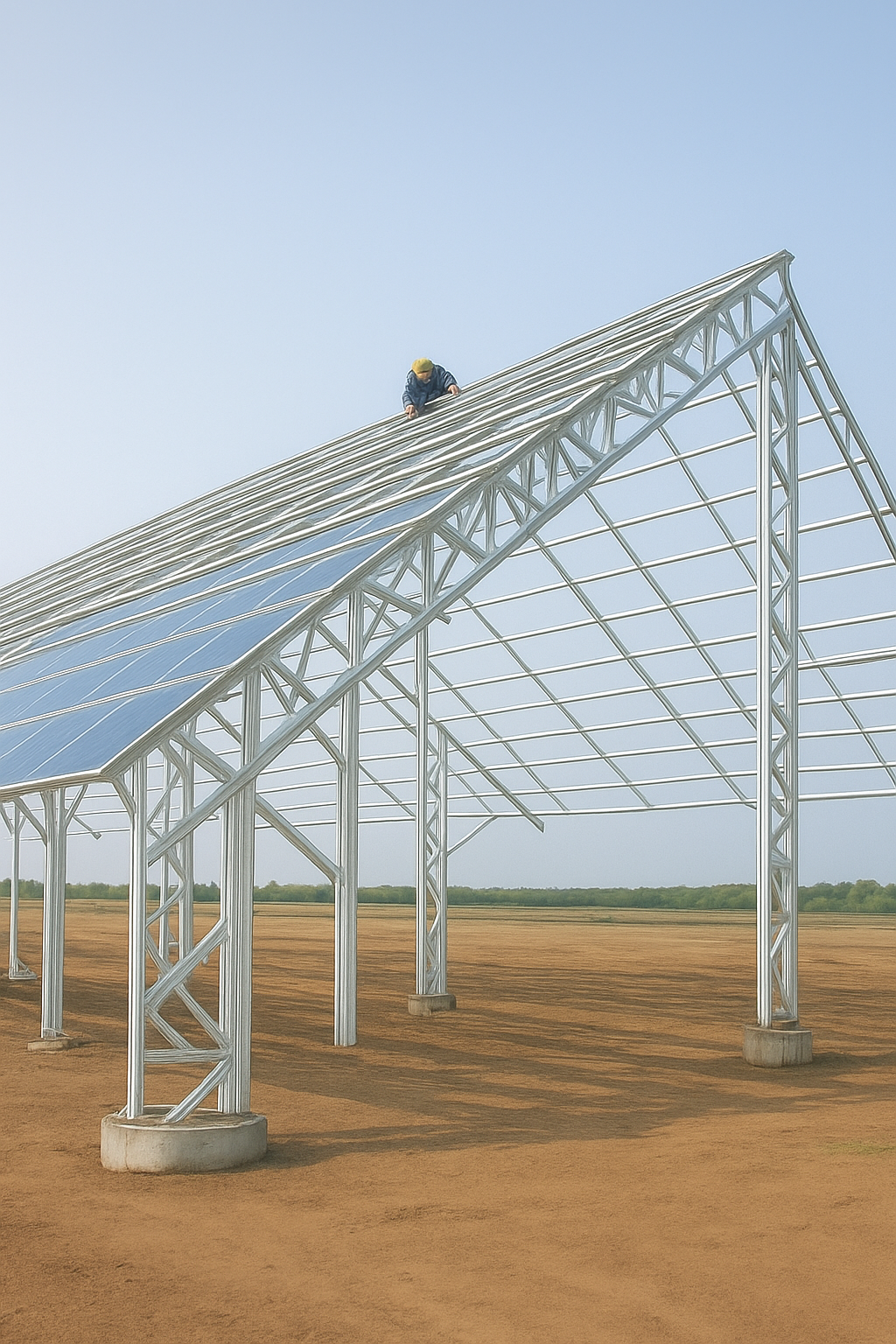

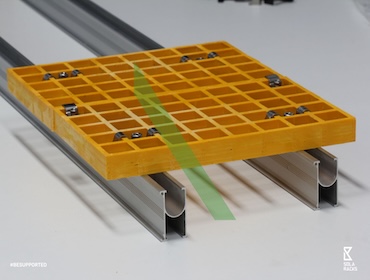

Mono Rail Profile

Material available - Aluminium

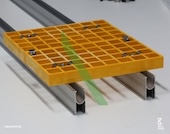

Walk Way

Material available - FRP

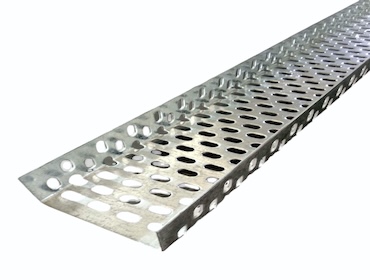

Cable Tray

Material available - Pre GI / GP

L angle profile

Material available - Magsure, Galvanium, Pre GI/GP, Hot Galvanised, HR(black), Stainless Steel.

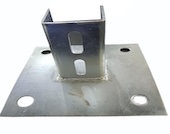

Base Plate

Material available - HR(black), Hot Galvanised

Jointer

Material available - HR(black), pre GI/GP, Hot Galvanised

Hanger / Degree Clamp

(L Bracket)

Material available - Magsure, Galvanium, Pre GI/GP, Hot Galvanised, HR(black), Stainless Steel.

Mid & End Clamp

Material available - Aluminum

Spring Nut, SDS &

Washer Nut

Material available - Zinc, Hot Galvanised, SS304

Hex Bolt & Allen Bolt

Material available - Zinc, Hot Galvanised

J Bolt & U Bolt

Material available - Zinc, Hot Galvanised,